Applications in an Automated World

Industrial instrumentation and control panels are the backbone of modern automation, giving you precise control and monitoring over your equipment and processes. These panels make it possible to manage everything from temperature and pressure to flow rates and machine operations, ensuring your London, Ontario area facility runs smoothly and efficiently.

With the right control panel setup, you gain fast troubleshooting, better safety, and less downtime. Whether you work in manufacturing, food processing, water treatment, or another field, a well-designed panel lets you quickly find and fix problems, saving both time and cost. Understanding the standards and best practices of panel design helps improve not only performance but also compliance with important regulations like UL 60947-4-1, NFPA 70, and NFPA 79 as shown by resources on industrial control panel standards.

Choosing the right components and layout for your control panel lays the foundation for a system that’s reliable and easy to maintain. By knowing what goes into making a strong, effective panel, you set your operation up for long-term success.

Fundamental Concepts of Industrial Instrumentation and Control Panels

Industrial instrumentation and control panels play a central part in automated processes. They help you monitor, measure, and manage everything from machinery to critical safety devices in plants or facilities.

Purpose and Role in Industrial Automation

Control panels in industrial environments serve as the central hub for managing machines, sensors, and various processes. You use these panels to start, stop, and adjust equipment actions. They are designed to collect signals from sensors, transmitters, or devices, and then process these signals to make decisions or provide feedback.

Automation depends on the fast and accurate exchange of information between different parts of a system. By unifying the operation of pumps, valves, motors, and more, control panels allow you to maintain quality, improve output, and detect faults quickly. Most panels handle coordinated responses, such as shutting down equipment if abnormal conditions are detected, to improve safety and reliability.

Key Features and Functions

Industrial control panels often include a combination of sensors, relays, switches, programmable logic controllers (PLCs), and communication modules. Common features are easy-to-read human-machine interfaces (HMIs), emergency stop buttons, and alarms for hazardous or abnormal system changes. You might also find local displays for readouts of temperature, pressure, or flow.

Modern systems often link these panels into a network for real-time data collection, trending, and remote control. Their functions go beyond simple control; they include monitoring, diagnostics, historical data recording, and communication with higher-level systems like SCADA or distributed control systems (DCS). These features make complex processes more manageable and allow you to react to data rather than guesses.

Types of Instrumentation Systems

You will see several types of instrumentation systems in use:

- Analog Systems: Use continuous signals, often for basic measurement and control tasks.

- Digital Systems: Transfer data using discrete signals, allowing integration with microcontrollers, PLCs, and smart devices.

- Pneumatic Systems: Rely on pressurized air, useful in environments where electrical equipment could be unsafe.

Field instruments may be installed directly at the process or on panels in a control room. You might pick between panel-mount and field-mount devices based on environmental challenges. Pneumatic systems can transmit signals short distances, while electronic and digital solutions reach farther and offer better accuracy and easier maintenance, as outlined on control.com.

Critical Components and Technologies

Modern industrial control panels rely on specialized equipment for safe automation and precise operation. These elements provide the structure for control, monitoring, and user interaction.

Programmable Logic Controllers (PLCs)

Programmable Logic Controllers are at the core of industrial automation systems. You use PLCs to automate machinery, processes, and safety systems. Their main strengths include flexibility, high-speed processing, and easy integration with other panel components.

PLCs continuously monitor inputs from sensors and switch outputs on or off as needed. This makes them essential for tasks like conveyor control, batch processes, and assembly automation. Most systems support standardized programming languages, allowing you to modify logic as requirements change over time.

You can scale PLCs with various input/output modules to fit complex systems or small applications. They also connect with HMI devices to give clear process feedback. For more details on how PLCs act as the “brains” in industrial control, see the industrial control panel components guide at rteng.com.

Key functions of PLCs:

- Read input signals from sensors and switches

- Execute pre-programmed control logic

- Output control signals to devices

- Monitor system status in real time

Human-Machine Interface (HMI)

The Human-Machine Interface lets you interact directly with the control system. HMIs present real-time data, alarms, and system status. Most common forms are touchscreens, digital displays, and simple panels with lights and buttons.

You can use HMIs to start or stop equipment, change setpoints, and view trending process variables. Well-designed HMIs improve safety and productivity by making system performance easy to monitor. Many offer remote access to view data away from the factory floor.

Common HMI functions include:

- Visual display of system and process data

- Real-time alarms and event notifications

- Data entry for commands and parameter changes

- Access to historical trends and reports

When paired with a PLC, an HMI can give operators early warnings or show which part of a machine is in need of attention. To learn about the roles these devices play, visit an in-depth instrumentation and controls guide.

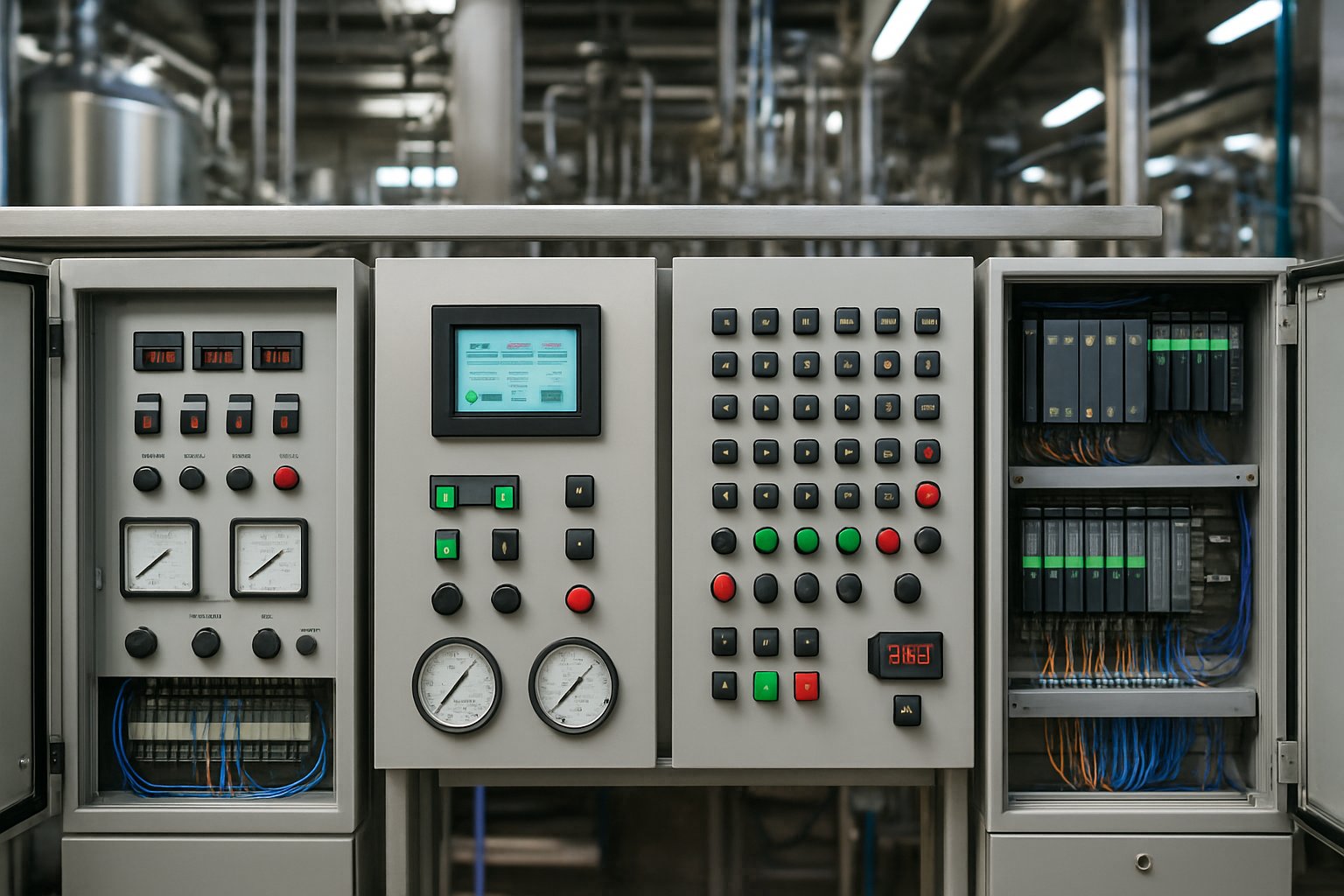

Operator Consoles and Interface Devices

Operator consoles provide a physical interface for users to control and monitor equipment. These consoles can range from compact panels to large desks covered in gauges, switches, and displays.

Simple operator consoles might feature illuminated pushbuttons, selector switches, and signal lamps. More advanced setups can include emergency stop controls, analog meters, and even small embedded HMIs. You typically place these at critical points in a plant to allow quick response.

A clear, organized layout helps prevent user error. Careful grouping of controls based on function supports fast decision-making. Safety interlocks and labeling reduce the risk of accidental operation. Having robust operator consoles is vital for efficiency and safety in industrial environments.

Typical operator console features:

- Mechanical and electronic switches for manual control

- Local indicators for system status

- Emergency shutdown and alarm functions

- Ergonomic design for ease of use

Remote Terminal Units (RTUs)

Remote Terminal Units are used for monitoring and control of processes over long distances. RTUs are vital for systems like pipelines, water treatment, or electric grids where direct connection is difficult.

You use RTUs to gather data from field devices and send control signals back from a central point. These units are built for harsh environments and can operate independently in case of network interruptions. RTUs communicate via various protocols, linking to a main controller or SCADA system.

Main RTU capabilities include:

- Collecting sensor data from remote sites

- Sending information to central systems

- Executing local control actions if needed

- Maintaining data logs until communication is restored

Using RTUs allows your system to expand to many locations, improving flexibility and reach. To explore the essential elements of these components, see the overview of industrial control systems.

Design Principles and Assembly Standards

Effective industrial instrumentation services and control panels require attention to panel layout, safe component integration, and strict compliance with electrical standards. Optimal designs use logical organization, clear labeling, and well-defined wiring routes to enhance both maintenance and system safety.

Control Panel Design Strategies

When designing your control panel, start by mapping out the system functions and determining the equipment each function needs. Panels should be organized to separate power and control circuits for easy troubleshooting. Grouping related devices and using labeled DIN rails keeps systems organized.

Consider the physical space inside the enclosure to avoid overcrowding, which can cause poor heat dissipation and make maintenance more difficult. Proper spacing supports airflow and reduces the risk of overheating, especially near key components like transformers and circuit breakers. Tools like electrical CAD software allow accurate planning of component placement to minimize wiring runs and save on installation costs. Document every design change to ensure consistent assembly and later upgrades.

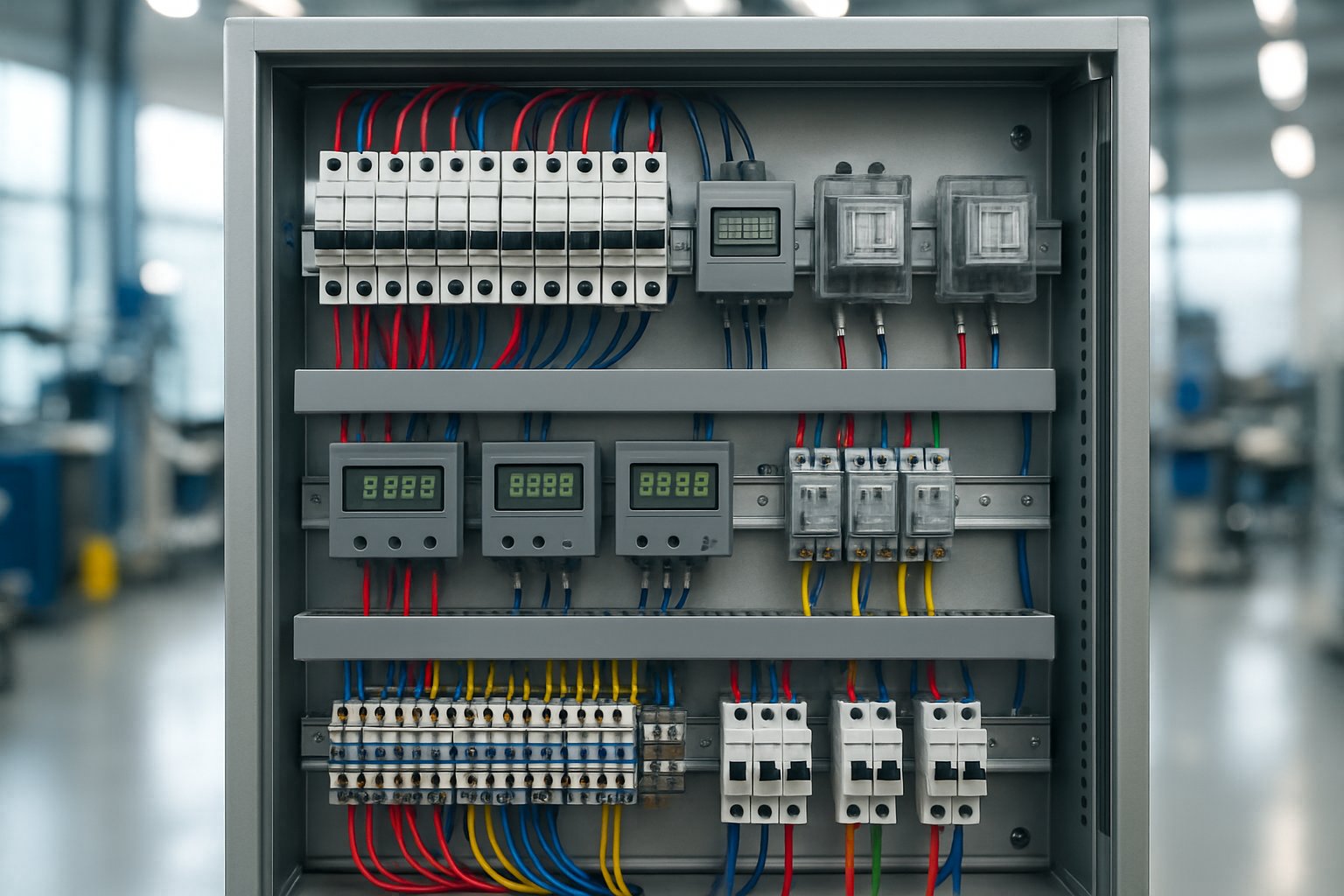

Industrial Wiring and Layout Practices

Industrial wiring should follow strict routing guidelines for safety and efficiency. Avoid running cables diagonally or across front panels where they could block device access. Use horizontal and vertical wiring paths with clear separation between power and signal lines to prevent electromagnetic interference.

Stranded wires are preferred because they bend more easily and can help dissipate heat better than solid core wires. Adding slack under wireways—not inside the working area—prepares your panel for future modifications. Proper cable management not only simplifies troubleshooting but also extends the life of your equipment. Clearly labeled wires and terminal blocks help technicians locate circuits quickly, minimizing downtime during repairs or upgrades. Learn more by exploring industrial control panel wiring and layout best practices at Control.com.

Component Selection and Integration

Choosing the right components for your control panel is essential for reliable operation. Select UL certified panels, transformers, circuit breakers, and relays that fit your voltage and current needs. Consider compatibility between all panel devices to avoid operational mismatches.

Integrating components requires attention to how devices interact. For example, select fuses or breakers with the correct interrupting capacity for your transformers and loads. Ensure signal and power circuits are properly shielded and separated, especially if your system includes sensitive instrumentation like PLCs. Using shielded cables for communication lines reduces signal noise from adjacent high-voltage circuits. Build redundancy into critical systems to improve uptime. Always verify certifications and specifications before finalizing designs.

Regulatory Compliance and Certification

Regulatory standards like NFPA 70 (NEC), NFPA 79, and UL 60947-4-1 set the safety and performance requirements for industrial control panels. Following these standards is mandatory for legal compliance and ensures panels meet strict electrical safety rules. These standards cover areas such as safe wiring practices, maximum panel voltages, required signage, circuit protection, and proper clearances.

UL certification for your control panel helps you meet inspection requirements and assures end users of the panel’s safety. Certification often includes tests for electrical endurance, short circuit protection, and grounding. Regularly review updates to standards, as regulations can evolve over time. For details, review these industrial control panel standards outlined at Control.com.

Types of Industrial Control Panels and Applications

Industrial control panels are designed to support safe, efficient, and reliable operations in a wide range of equipment and automation systems. Each type of panel has features and components selected for specific uses such as electrical power distribution, automation, motor control, or equipment integration.

Power Distribution Control Panels

Power distribution control panels deliver and regulate electrical power to machinery, motors, lighting, and other industrial systems. These panels typically include main circuit breakers, protective fuses, busbars, terminal blocks, and surge protectors.

If your facility requires reliable electricity management for heavy equipment, these panels play a critical role in handling both high and low voltage circuits. Many also provide the ability to monitor system loads and isolate sections for maintenance without disrupting the complete operation.

Clearly labeled wiring ensures safe installation and simplifies troubleshooting during faults. Power distribution panels remain the backbone for most manufacturing and process industries. They are often built to comply with strict codes and standards for electrical safety, protecting people and property.

Automation and Process Panels

Automation and process panels support control of complex industrial workflows. These panels use programmable logic controllers (PLCs), relays, timers, and a range of sensors and actuators for automated process management.

Panels of this category manage everything from conveyor operation to batch processing and chemical dosing. You can easily reprogram these systems for new products or production lines, which improves flexibility.

Human-machine interface (HMI) screens and remote connection options are often included. These give maintenance teams direct access to real-time data and can simplify diagnostics and troubleshooting. Modern automation panels help optimize process efficiency and reduce manual interventions.

Industries such as pharmaceuticals, automotive manufacturing, and food processing rely heavily on effective automation panel design for reliable, consistent operations. For more technical depth about automation controls, the overview at palmerdcs.com gives examples of real applications.

Custom Motor Control Centers (MCC)

Custom motor control centers (MCC) organize motor starters, contactors, overload relays, and power supplies within a single, modular enclosure. MCCs simplify wiring, maintenance, and expansion for sites with many electric motors.

You’ll find MCCs used in pulp and paper mills, water treatment plants, and heavy manufacturing. These panels allow grouping of multiple motors, each with its own protection and manual or automatic control. Custom features might include soft starters, variable frequency drives, and advanced metering.

When you need to upgrade or integrate new motors, modular construction makes it easy. Openings are left for future additions, which saves space and cost over time. Effective MCC design reduces downtime by allowing quick isolation and repair of individual motor circuits.

OEM and Custom Solutions

Original equipment manufacturer (OEM) and custom solutions are designed to meet your specific equipment needs. These panels can be highly specialized, integrating with unique machines or production processes.

Every OEM panel is built for the exact requirements of the equipment it serves. Custom engineering includes the right enclosure size, wiring paths, connectors, and digital interfaces. This ensures compatibility and plug-and-play installation.

You can request additional features, like remote monitoring, special documentation, or backup power support. Leading suppliers use quality components for long-term reliability and meet important industry standards. Custom industrial control panels provide unique benefits that generic, off-the-shelf options cannot, as covered in more detail at palmerdcs.com.

Considerations for Implementation and Future Trends

Successful industrial instrumentation and control panel projects depend on following correct installation steps, staying updated with modern automation advances, and planning for future upgrades. Paying attention to these areas helps you lower downtime, boost efficiency, and respond well to changes in technology.

Installation and Maintenance Best Practices

When installing industrial control panels, you should start with precise documentation. Schematics and wiring diagrams help with correct assembly and future troubleshooting. Always use clear labeling for terminals, cables, and devices.

Regular maintenance is essential for safe and reliable operations. Set up a checklist for inspections, which should include thermal scanning, visual checks for wear, and cleaning dust build-up. Keep spare fuses, relays, and contactors handy.

Testing every control and protection circuit before starting production lowers the risk of failure. Choose panels approved by recognized standards, as outlined by UL 60947-4-1 and NFPA 70 for design and safety.

Integration with Modern Automation Systems

Modern automation needs seamless integration between control panels and technologies such as PLCs, SCADA, and manufacturing execution systems (MES). Ethernet-enabled devices make real-time data sharing possible, speeding up decisions and process control.

When planning integration, focus on open protocols like Modbus or OPC UA for better compatibility between various equipment brands. Digital sensors and smart devices on your panel expand monitoring abilities and support faster troubleshooting.

Wireless sensor networks and IoT platforms are also on the rise, helping connect remote sensors and actuators for more flexibility. Upgraded interfaces and touchscreen HMIs now offer easier access to system data and alarms, making equipment safer and more user-friendly. Following these practices ensures your panels fit easily into both legacy and new automation setups.

Future-Proofing and Technological Advancements

When future-proofing your industrial control panels, select modular and scalable hardware. Modular designs let you add or swap components as plant needs change, saving on costs and labor. Choose control systems with remote update features so you can easily deploy firmware or software improvements.

Anticipate that advanced analytics, cybersecurity requirements, and AI-driven control will reshape how instrumentation is used. Smart panels using real-time diagnostics and predictive maintenance are gaining ground. According to recent trends, AI is starting to make process decisions, with less need for human oversight.

Keep up with industry standards. Being ready for technologies like edge computing will allow you to adapt systems quickly, cut downtime, and respond fast to customer or production changes.

Frequently Asked Questions

You need a good understanding of hardware, safety codes, and custom solutions for reliable industrial automation. Knowledge of the most common challenges and best practices helps reduce downtime and supports safe operations.

What are the main components of an industrial control panel?

Industrial control panels include devices like circuit breakers, relays, fuses, transformers, programmable logic controllers (PLCs), and human-machine interfaces (HMI). Circuit breakers and fuses protect equipment from overloads and faults.

Relays and contactors manage power flow, while PLCs automate processes and respond to input signals. HMIs let operators monitor and adjust settings easily. For detailed info on panel components, see this comprehensive guide to industrial control panels.

How do you ensure compliance with safety standards for control panels?

You must design control panels according to recognized industry standards for electrical safety, such as NFPA 70 (National Electrical Code) and UL 508A for industrial control panels. These standards cover wiring, grounding, component selection, and enclosure ratings.

Proper labeling, insulation, and quality testing are critical before the panel goes into operation. Using certified components also helps you meet regulatory requirements; review control panel design standards for more important details.

What are the differences between standard and explosion-proof control panels?

Explosion-proof control panels are built for hazardous environments with flammable gases, vapors, or dust. These enclosures prevent internal sparks from escaping and causing explosions. They use heavy-duty materials, special seals, and certified components to contain ignition sources.

Standard panels are used in non-hazardous areas where this level of protection is not required. You need to follow strict codes and testing procedures for any panel installed in hazardous zones.

How can custom control panels be designed to fit specific industrial applications?

Custom control panels are engineered after evaluating your specific automation or power needs. Design starts with a discussion of your equipment’s voltage, current, environmental conditions, and required functions. Each component is selected for reliability and safety based on your use case.

Wiring, enclosure type, and the layout are then refined, and thorough testing follows. To understand more about designing tailored control panels, see this control panel design guide.

What are the best practices for maintaining and troubleshooting industrial instrumentation?

Regular inspections help catch loose wiring, signs of corrosion, or worn components early. Scheduled cleaning and calibration of sensors ensure accurate readings and stable operations. Using correct labels and up-to-date schematics simplifies tracing problems.

If a problem happens, start by checking fuses and breakers. Clear wiring diagrams and proper documentation speed up troubleshooting. Training staff in basic diagnostic steps helps prevent small issues from causing major shutdowns.

How do motor control panels integrate with overall industrial automation systems?

Motor control panels communicate with PLCs and automation equipment using standard protocols and inputs. They allow central control of on/off functions, motor speed, and monitoring through sensors.

This integration means operators can start, stop, and protect motors from a control room HMI or remotely. These panels often include overload relays, variable frequency drives, and soft starters to support advanced automation needs. For more, you can study the range of industrial control panel types and functions.